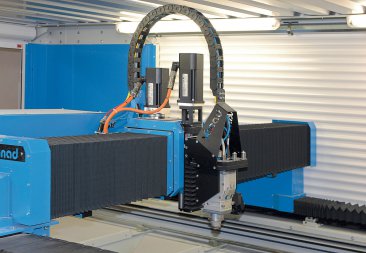

Vanad KOMPAKT Laser for the fastest, as well as very economic cutting

The CNC machine Vanad KOMPAKT Laser enables extremely precise, fast and highly efficient thermal cutting of materials. Its design makes it suitable for use in small, medium-sized and large operations or for pre-production series.

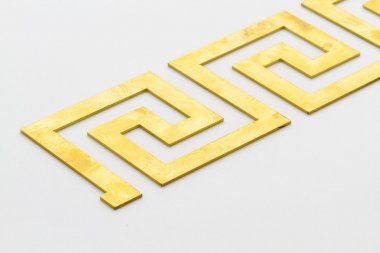

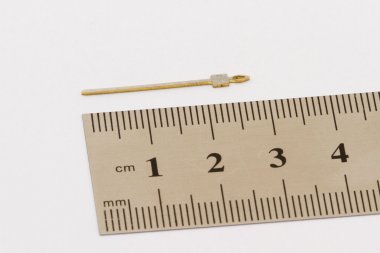

Thanks to minimal kerf and low heat influence of material, the highly focused laser beam allows for the common line cutting of the material.

You can choose from a large number of supplementary fittings.

Models of material grids

for Vanad KOMPAKT Laser

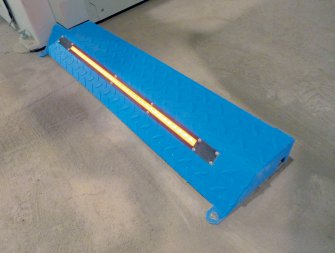

A - Manually extendable grid

B - Motor-powered extendable grid

C - Two hydraulically exchangeable grids

D - Two manually extendable grids

Features of the machine KOMPAKT Laser

- The fiber laser is the most preferable laser of all types. Its endurance is astounding up to 100 000 hours.

- Although it has the same efficiency as CO2 laser, its energy consumption is significantly lower - you save on operating costs.

- It is easy to assemble and handle thanks to its solid construction.

- It also manages a precise cutting of complex shapes.

Look how accurately the Vanad KOMPAKT Laser cuts.

Please contact us for a free quotation for the CNC machine KOMPAKT Laser.

.

The focused beam of the fiber laser cuts metallic and non-metallic materials of ordinary formats such as mica

plates, HSS sheets, klingerit, mirelon, polyethylene foam,

anti-vibration rubber, cardboard, cork, brass, bronze, copper,

corrugated cardboard and tar paper.

Equipment

Standard equipment

- Flexible energy chains in all axes

- Transfer of cutting data via the LAN network, Wi-Fi or USB

- Reliable B&R control system

- Laser marking unit

- Capacity control of the height of the cutting head

- Controlled piercing for longer lifetime of costumables

- Own anti-collision head system

- Protective filter – 1 sight glass of A4/A3 size

- Camera for monitoring of the cutting and its display on a separate monitor

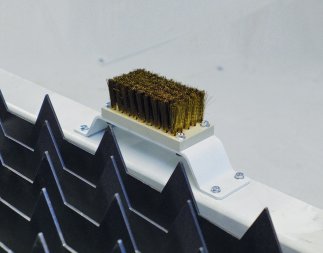

- Manually extendable grid

- Sectional extraction of the material table

Optional equipment

- Safety light curtain around the extended grid

- Conveyor belt

- Electrically controlled sliding grid

- Two hydraulically exchangeable grids for minimisation of the preparation time

- Large size side windows

- CAD/CAM software for the preparation of cutting data

- Protective bellows on all axes

- Cleaning of nozzle

- Remote control

- RotCUT device for tube and profile processing

Software

Operation system

The B&R control system is used also for the CNC machine Vanad MIRON Laser, which is easy to handle and enables accurate laser marking and cutting.

CAD / CAM software for nesting

Laserové stroje Vanad mohou využít rozsáhlou škálu software pro přípravu pálicích plánů, jako jsou programy WRykRys, LANTEK Nesting, Hypertherm ProNest, RADAN, SAPS a další. Tyto programy pokrývají většinu požadavků.

.